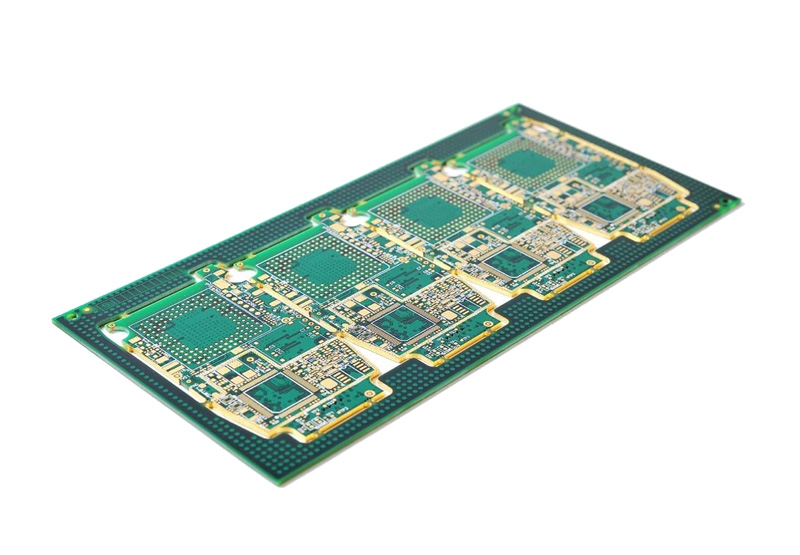

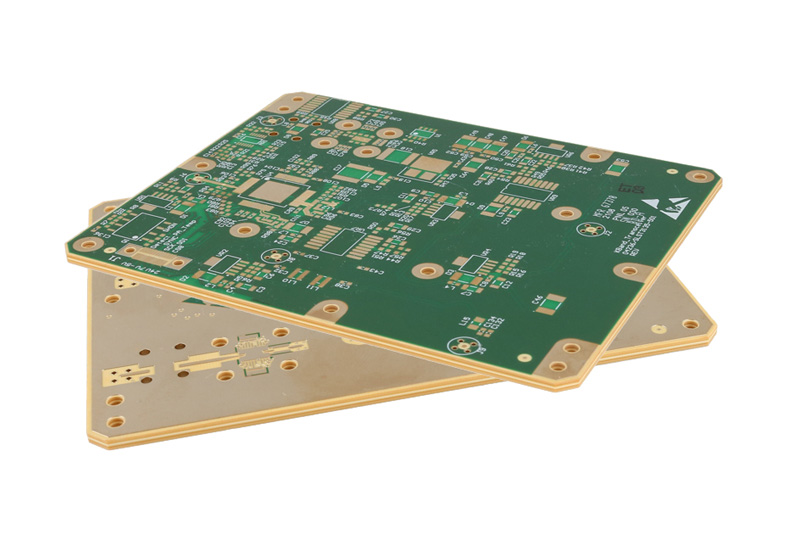

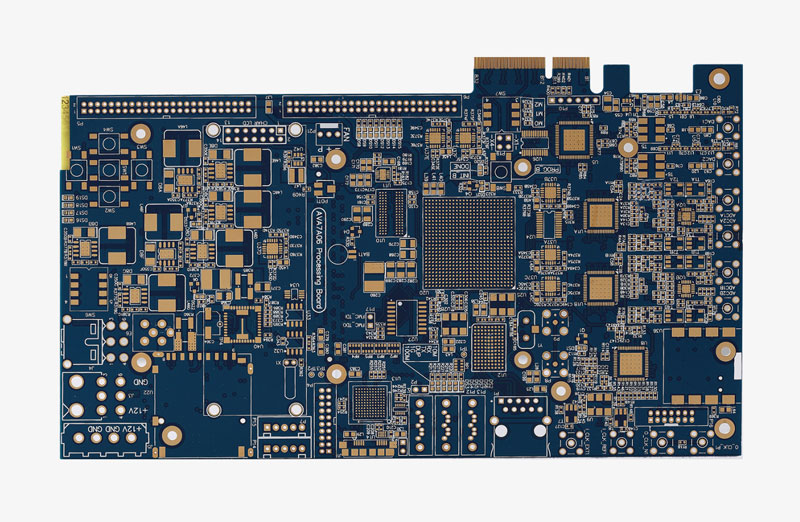

Printed Circuit Board

As your EMS provider, our obligation is to guarantee you a resilient and durable electronic board. As a first step, we need to start by receiving a solid and well-manufactured bare PCB.

For that reason, we have partnered up with world-class PCB factories that use state-of-the-art equipment and follow rigorous processes.

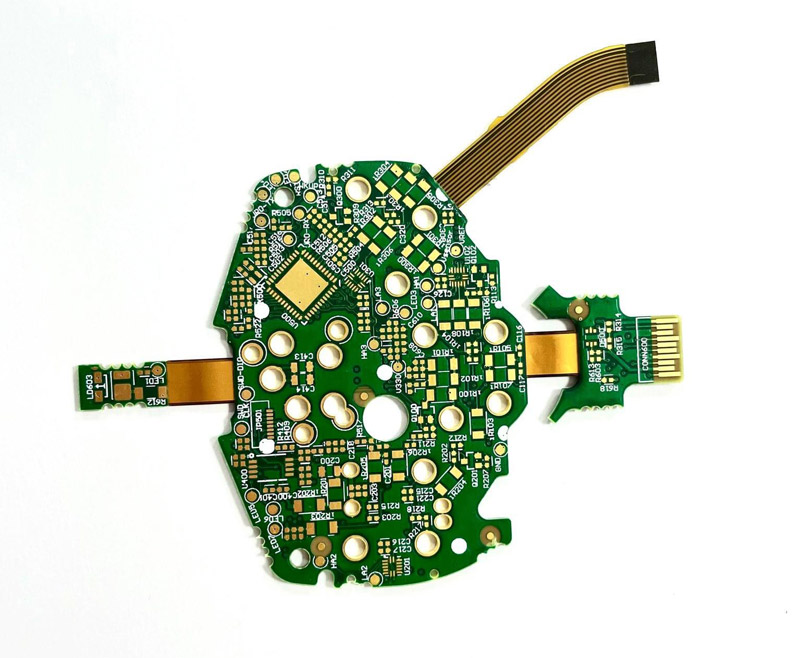

Flex and Rigid-Flex

The flex and rigid-flex printed circuit board technology offer a space-saving method for integrating multiple circuit board assemblies in complex environments and for eliminating wires, cables, or connectors – these are replaced by flexible PCBs between rigid sections.

Flexible PCBs enable the circuit board to adapt flexibly to a desired shape and bending, the best suitable and customized for your application.

• One-sided flexible material

• Double-sided flexible material

• Multilayer flex with plated through holes and in combination with HDI technology

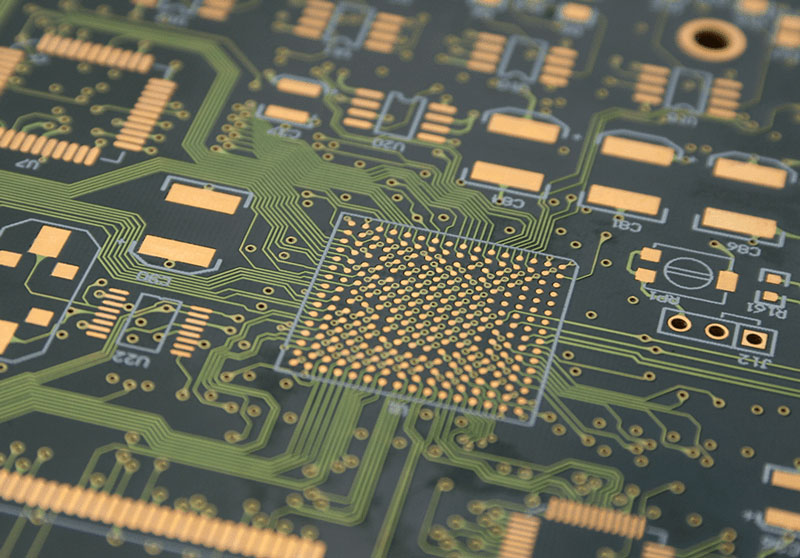

High Density Interconnect (HDI)

Technological improvements and advancements have resulted in printed circuit boards (PCBs) increasingly dense with steadily improved performance.

The miniaturization and increase in performance of components and semiconductors inevitably drives the technology of the printed circuit board, which leads to the design of finer structures, high-performance materials and laser-drilled micro-via. Micro-vias enable the connection from one copper layer to another within a PCB. Vias on different layers can be staggered and can be plugged with copper or epoxy.

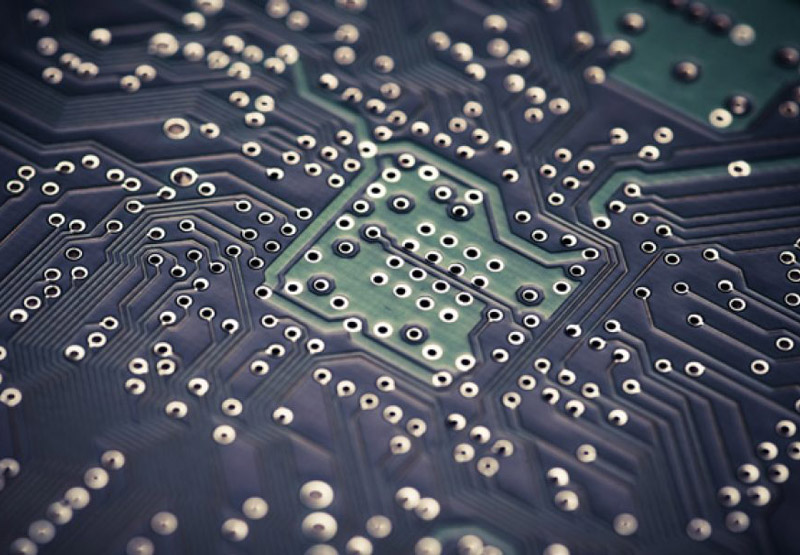

HighSpeed & HighFrequency

Due to the steadily increasing transmission frequencies of electronic components, the need for low-loss in the frequency range of several GHz, high-frequency signal transmission between the components has become extremely important. Inadequate transmission lines lead to reflections and thus to undesirable effects at the end of the line. Signal source + transmission line + receiver must have the same impedance.

PCBs with defined impedance and transmission characteristics are usually based on special materials:

• PTFE materials

• Low dielectric loss

• High or even low dielectric constant

• Mixture buildups with different performances (e.g. conventional FR4 in combination with special RF / HF materials)

• Special base copper and plating, as well as special surface finishing best suitable for high-performance RF and Highspeed applications

Technology & capabilities

• Flex up to 8 layer

• Rigid-flex up to 20 layer

• Rigid Multilayer up to 40 layer

• Max. thickness 5.6mm

• Line and Space 3mil (75µm)

• HDI with Blind / Buried / Stacked / Staggered Vias

• Hybrid Boards

• Impedance controlled

• Laser drilling

• Edge / Slot Metallization

• Via In Pad

• Plugging with Copper / Epoxy / Soldermask

• Mixed Surface Finish Options

Surface Finishing & Materials

Materials:

• Isola

• DuPont

• Taiflex

• ITEQ

• Arlon

• Rogers

• Panasonic

• Nanya

• Nelco

• Taconic

• Others on request

Surface Finishing:

• HASL

• Immersion Tin

• ENIG

• ENEPIG

• EPIG

• Softgold

• Hard Gold